Bending Active Systems: Bamboo Research Pavilion Using Robotic Arm and Steam Bending

In this course, students engage with the process of material distribution and designing, tooling, testing, prototyping and true-scale fabrication using bamboo, a meticulous endeavor that extends the sphere of their architectural education.

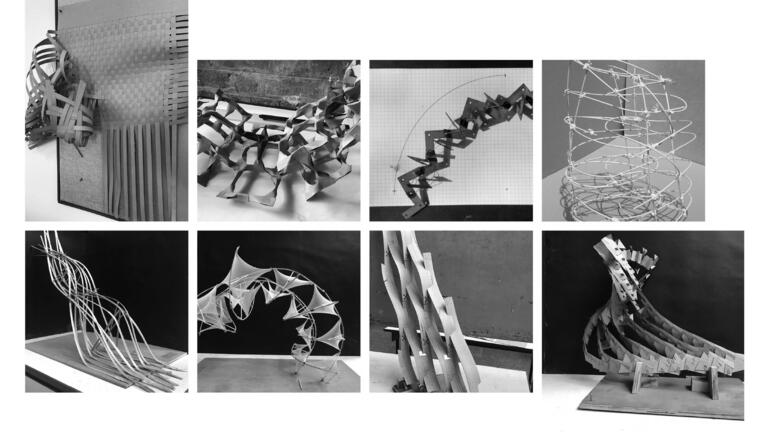

Bend Active Spanning

Bamboo, a material brimming with immense, yet largely unexplored, potential, particularly within the realm of architecture, stands as a testament to nature’s ingenuity. In the current scenario, this fast-growing, low-cost, carbon-sequestering natural resource remains an unconventional material in the practice of architecture, always given the peripheral roles of scaffolding and at times not much more than that. The potential of such a versatile material remains highly underutilized. It’s time to shift our perspective and explore the full potential of this protean material in the 21st century.

Bamboo is grown extensively in the developing parts of the global south, and tooling it has predominately relied on traditional techniques. Bamboo embodies flexibility, stiffness and efficiency in material distribution, yielding lightweight yet efficient systems. It has high resistance to tensile stresses, buckling and bending stresses, and its elastic properties are remarkable. The existing research taps into these properties of bamboo to arrive at a spanning and spatial system that takes advantage of the material’s intrinsic properties. Traditional ways of using bamboo as a whole culm (cane) restrict its spanning and bending abilities, making it more vulnerable to splitting. Bending activates the tensile capacity of bamboo and allows for more efficient material distribution.

Combining bamboo and digital fabrication enables radically unique and spatially versatile configurations. Digital fabrication with this irregular material is challenging but immensely rewarding, unlocking new possibilities for shaping this material. CNC routing can offer efficient and precise sectioning of bamboo culm, and bending bamboo using robotic arms reduces the burden of a custom jig for each new bend profile.

The research strives to derive material systems configured using variable cross-sections of bamboo culm across its length to explore its spanning potential. Variability in cross-sections responds to different positions, bending, loading conditions and roles of members in the larger spanning system. The process of material distribution and designing, tooling, testing, prototyping and true-scale fabrication is a meticulous endeavor that extends the sphere of architectural education. Students in this course will work with this low-carbon material, making architectural education more tacit and hands-on to align well with the school’s pedagogies. The research allows a demonstration of the potential of this low-carbon material to inform and propel the practice of bamboo in different building systems and mainstream practices in areas where bamboo naturally grows. The current climate crisis necessitates a shift towards low-energy practices, and this research is a step in the right direction.